Erik MacLennan and I have been working on 3D printers jointly this last year. We have also started a 3D printing hub that offers printing services to primarily local Vancouver costumers through an online platform, 3D Hubs.

In addition to giving challenging print jobs, this project has put us in contact with interesting people and given insight into customer service and advertising.

To the right we see three classical Thingiverse models, printed in ColorFabb WoodFill that contains 30% recycled woodfibres.

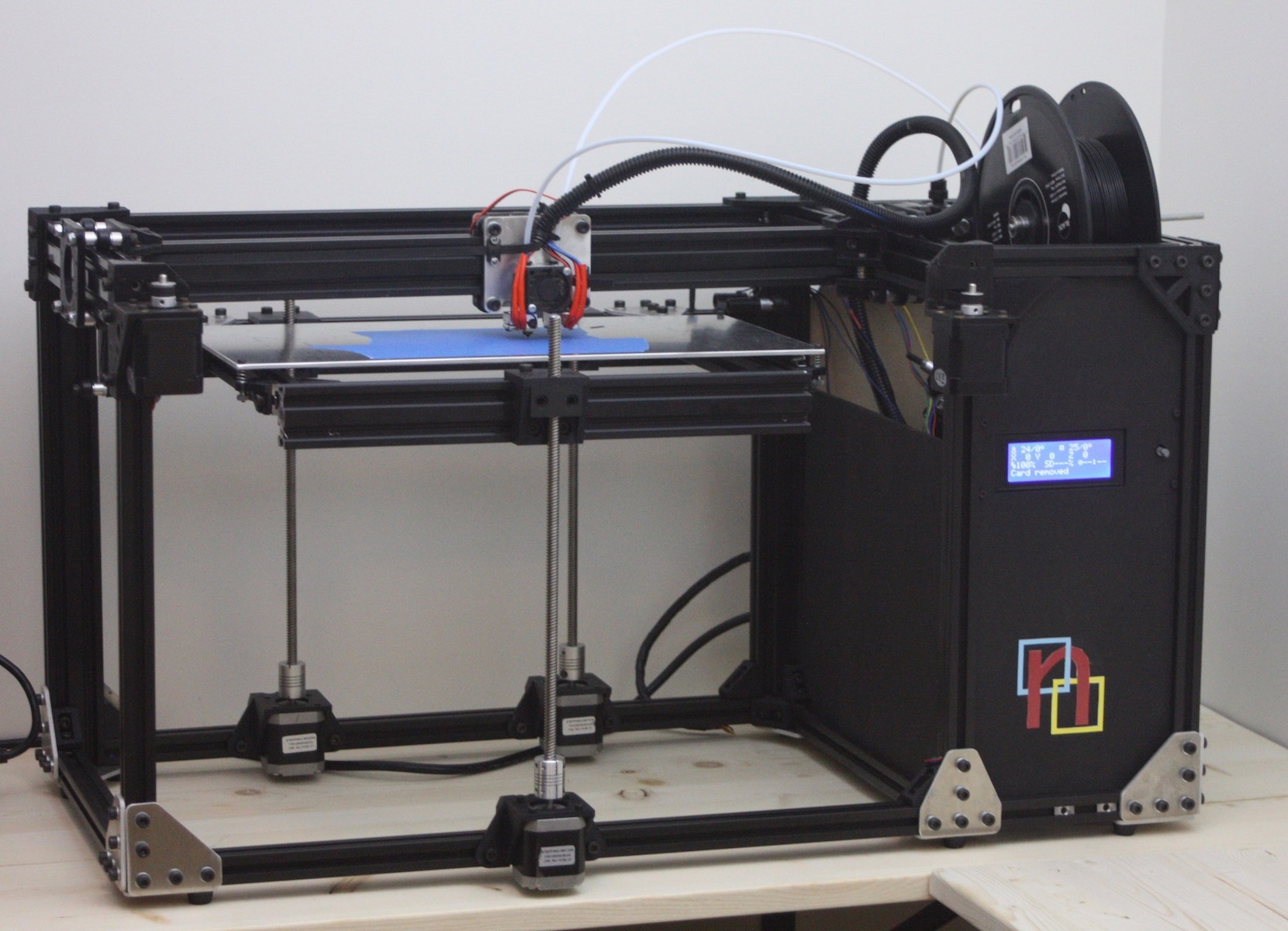

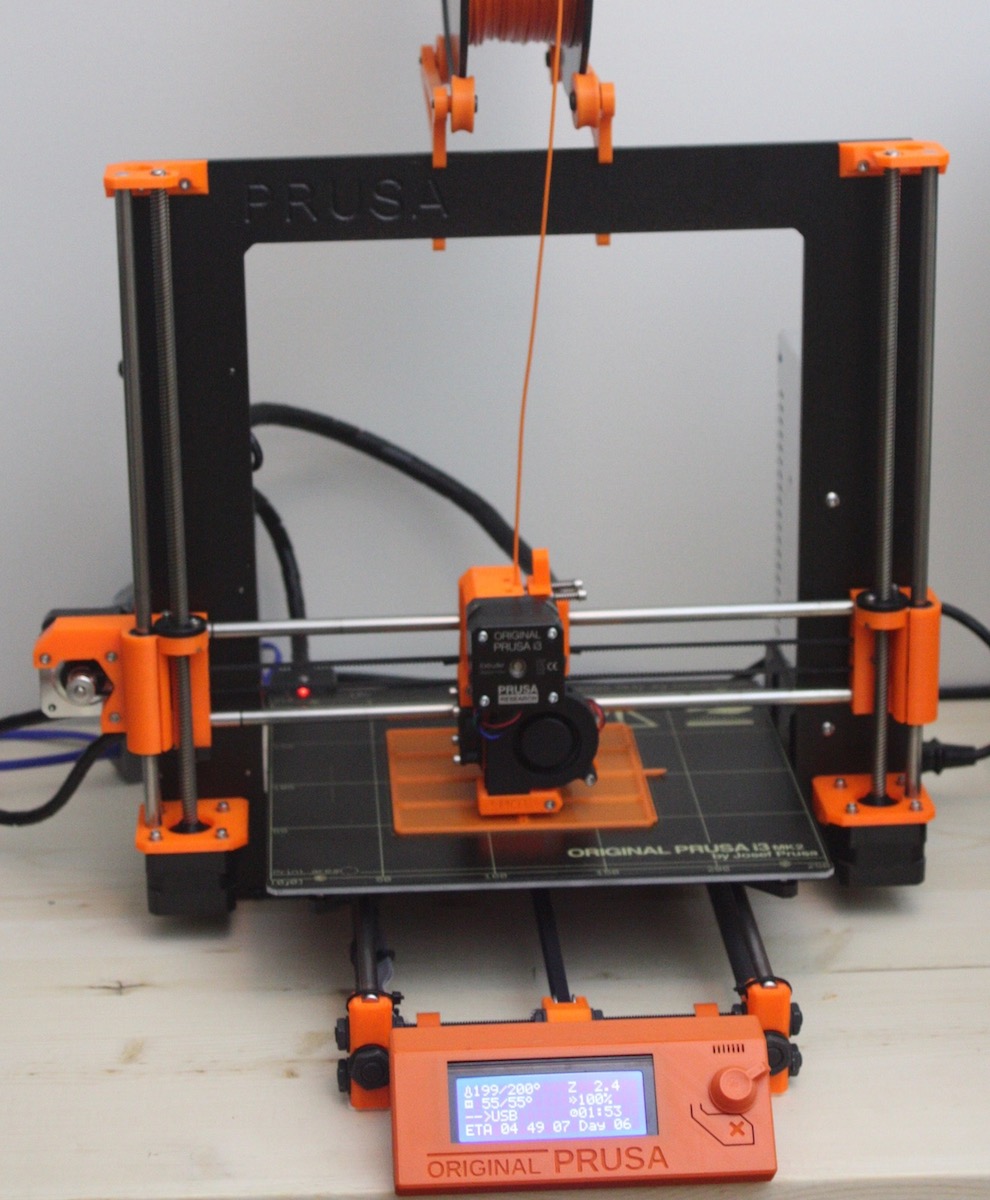

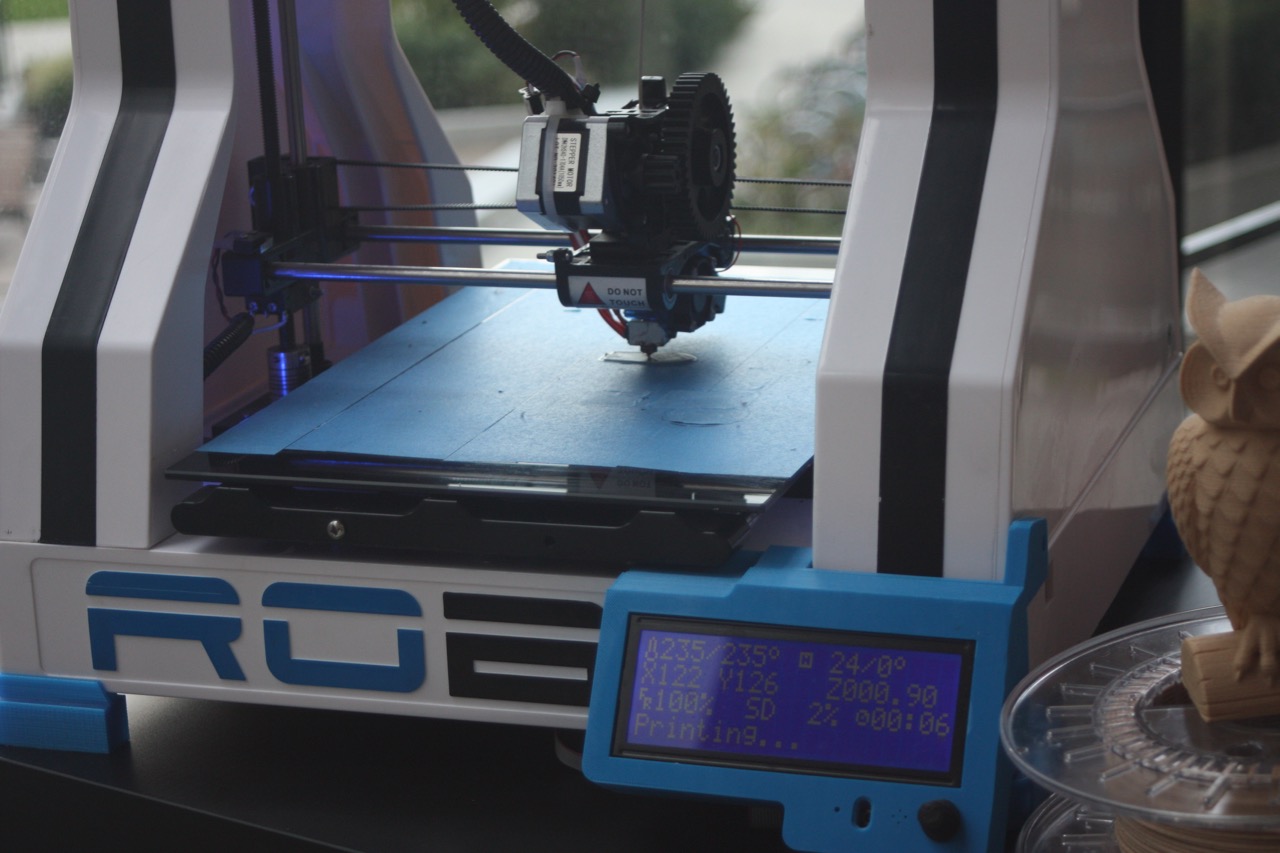

Below we have Erik (right) and me in front of our current printer setup.